Electric Vehicle (EV) Paint Systems

Taikisha USA Inc. can provide complete paint systems for electric vehicle manufacturing.

Taikisha USA: Your Partner For EV Production

Integrating an electric vehicle body into an existing paint process can be a cost-effective solution when compared to building a new dedicated paint line. Taikisha USA has experience working with its customers on developing and integrating these solutions to meet the unique demands of producing EV’s.

Total Engineering

for EV Production

Taikisha USA employs a large staff of full-time engineers. From sizing equipment based on heat loads and specifications to designing new layouts for brand new paint shops, our Engineering & CAD team can provide full-service engineering. We design custom paint booths, industrial ovens, and other paint process equipment for Electric Vehicles.

General Contractor for

Complete Construction

Taikisha USA is a General Contractor for building new Electric Vehicle (EV) manufacturing plants, offering turn-key services including project management, fabrication, installation, engineering, design, drawings, construction site supervision, oversight of skilled trades and subcontractors, quality assurance, start-up, commissioning, and spray trials.

Modular Design Offers Flexibility & Customization

Every OEM's paint shop is different. Taikisha USA offers each paint system equipment, including a wide breadth of standard products that can be fully customized to your unique process needs. We specialize in providing full-service custom designs & custom engineering for each client for their portfolio of electric vehicles (EVs).

Complex Body Structure

EV’s typically have a complex body structure that can be a challenge to uniformly and completely cure in the ovens of a paint shop.

- EV’s require heavily-reinforced rocker panels and B-Pillars to carry and protect a battery pack mounted on the underside of the body. These heavy metal sections require more time and energy to properly cure. EV rocker sections can be twice as thick, over 6mm, and take twice as long to reach temperature inside the paint cure oven. Ovens for EVs typically need to be extended to provide sufficient heat-up time. However, TKS' expertise in CFD, air flow control, and nozzle positioning allows us to minimize these increases.

- Electric vehicles typically bring a prevalence in mixed-metal body designs and as well as increased use in structural adhesives for panel joining to keep the body rigid and safe, while still as light as possible. These materials must be delicately heated to prevent the adhesive material from breaking down and to reduce thermal stresses on thin metals to eliminate any warping.

Retrofit Existing Ovens

For existing ovens, TKS can offer a retrofit solution that may include: an extension to lengthen the cure oven or add a pre-heat zone, an increase in overall heating capacity via adding new heater boxes, re-locating oven nozzles to target the rocker section, and re-balancing of heating zones to effectively cure all areas of the body in addition to any structural adhesives or glues without creating over-bake conditions. We conduct a full-concept thermal CFD simulation to ensure the effectiveness of the design for all car bodies prior to installation and on-site trials.

Traverse & Longitudinal Ovens

TKS has multiple solutions for a new oven installation centered around the design of your electric vehicle. Longitudinal ovens can be designed with a lower-section of nozzles dedicated to the curing of heavy-metal areas, while maintaining an even and effective cure of the rest of the body. Indexing (stop-and-go) conveyors can be utilized to locate large nozzles at key areas of the body. TKS also has experience with the design and installation of a transverse, stop-and-go oven concept. In this design, the vehicle body moves through the oven sideways. The primary benefit of this concept is that it can effectively heat the body from the inside out, utilizing large nozzles through the windshield area, as well as using nozzles to target the ends of the rocker structure, A-Pillar lower, and door hinge areas. Finally, the Traverse Oven allow us to target heavy areas (i.e. 6.0mm rocker) first while allowing a more gradual heat-up of sensitive areas (i.e. 0.7mm roof panels).

Double Cooling Capacity

Once the body has been heated through, fully cures, and exits the paint oven – now we have the same challenge in reverse – cooling the body’s thickest sections. In our experience, a doubling of the cooling capacity and/or length may be required. Often times in a retrofit or conversion of ICE paint line to an EV paint line, the floor space is not available to double the length of the cooler.

Evaporative Cooling System

If your plant is limited on floor space and unable to expand the cooler, one option is to look at a different cooling technology, such as TKS’ evaporative cooling system. Using a fine, aerosolized RO mist, the tiny water droplets hit the hot vehicle body and vaporize, pulling away thermal energy using evaporative cooling. This method is especially effective for cooling after hotter ovens, such as ED/E-Coat oven cooler, and Sealer oven cooler. Exiting these ovens, the body is much hotter and the RO water will vaporize more readily.

Using the evaporative cooling in the first zone, we can employ a traditional chilled air cooling method in Zone 2, once the body has cooled down below the boiling point of water (~212°F).

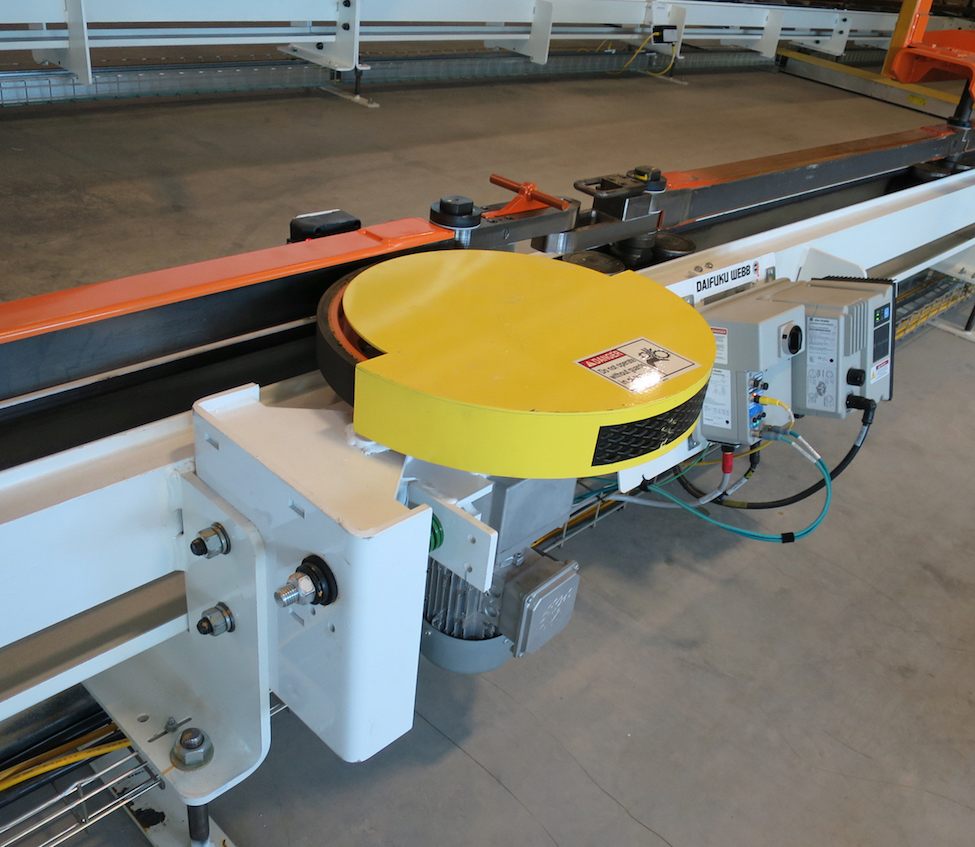

Body Conveyance

EV body designs may not be able to use the same pick-up points as other body types that are running through the same line. When common pick-up points are not possible, TKS can help to evaluate the carrier design and suggest changes or pick-up points to minimize the overall effect on your conveyor and conveyance systems in your existing paint shop.

Coating of Auxiliary Parts

Many EV’s have parts that require similar coatings or finishing to the car body, but are assembled in a separate process or are not feasible to process with the car body. Battery packs, for example, are typically manufactured and assembled in a separate process than the body, joining later in the assembly area.

TKS can offered tailored, flexible solutions for the e-coating and painting of auxiliary parts separate from the bodies. Often times, these lines will have parts of multiple shapes and sizes, and our expertise will allow us to design a system that is flexible enough to uniformly coat parts of differing sizes and complex geometries.

Body Distortion / Flexing

Lightweight body designs is often a point of emphasis in EV’s to maximize range, but these lightweight solutions require more delicate handling. Particularly in Pre-Treatment and E-Coat dip stages, thinner body panels or parts with structural adhesive could be more prone to distortion if the dip path is not handled correctly.

TKS can offer flexible dip-coating solutions, with individual dip curves tailored to each body type to minimize panel distortion and maintain a repeatable process.

Pre-Treatment Systems

When converting an existing line to paint EVs, there's typically many process and chemical changes associated with more mixed-metal & aluminum content. Most Pretreatment and Phosphate systems need to be converted from a traditional Zinc Phosphate dip to a new Zirconium Oxide (Metal Oxide) chemistry to be more compatible with the Aluminum content. Other upgrades to accommodate a change in chemistry or pre-treatment product may be required. TKS can coordinate these process, piping, filter, and chemical changes with your chemical supplier: PPG, BASF, Chemetall, etc.

New Greenfield Plant Considerations

When considering a new greenfield paint shop for electric vehicles, TKS can work with you to consider a phased installation: low JPH, low initial investment to get started, designed in a way to easily expand and increase production in the future. New plants can consider integrating new technologies like dry scrubber spray booths, automated defect detection / robotic surface inspection, automated sanding and finesse, Industry 4.0 (IOT) and Smart, Connected Paint shop capabilities.